METROLOGY & LASER LAB

DUDL 3443

Overview

This lab is featured in a junior level and senior level manufacturing processes labs and is available for research. Students are tasked with macro and micro-indention material hardness measurement (Rockwell, Brinell, Vickers and Knopp Scales), tensile and compression testing, height-scale on a surface plate; caliper, micrometer and laser-mic application and operation. At 1,350 ft² of clean-room with climate-controlled environment, the lab features a Coordinate Measurement Machine (CMM) and a Roundness Gage to measure part characteristics; also features a part profile measurement capability by projecting a part “shadow” against a measuring scale and a separate roundness test to measure part concentricity.

Features & Equipment

Mitutoyo Coordinate Measuring Machine (CMM)

- Capability: Measures the geometry of an object by sensing points on its surface with a probe.

- High Precision: measurement accuracy down to microns, typically 2-3 microns depending on the model.

- Multiple Probing Options: They support touch-trigger probes, scanning probes, and optical sensors for versatile measurement tasks.

- Large Measurement Volume: Ability to handle parts with volumes up to several cubic meters, suitable for both small and large components.

MTS Ultimate Test Module (UTM)

- Capability: Static test systems and monotonic test systems; and are the standard for determining basic material properties

- Load Capacity: The UTM is designed to handle a wide range of loads up to 1,000 kN

- Multi-Axial Testing: It supports multi-axial testing capabilities, allowing for the evaluation of materials and structures under various load conditions, including tension, compression, and bending.

- Advanced Control System: Real-time data acquisition and analysis, enabling precise control of test parameters and immediate feedback on material performance.

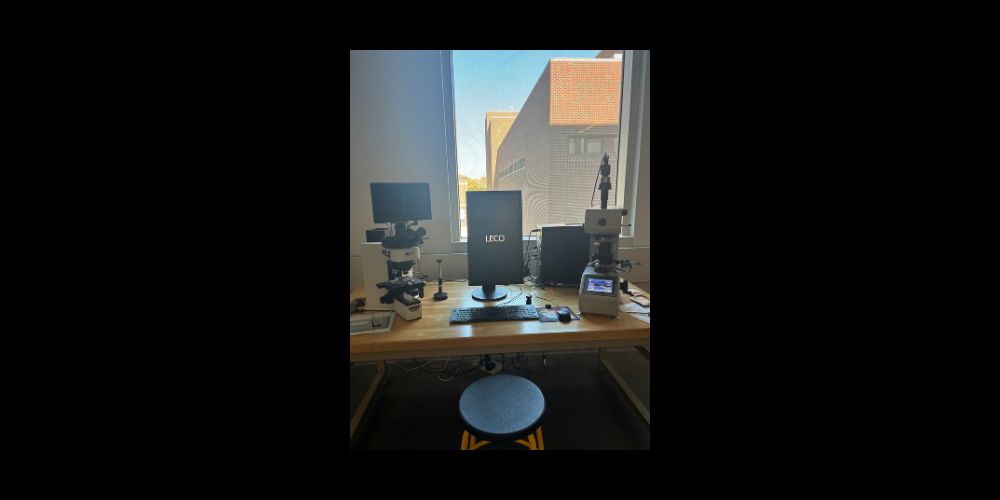

LECO Microhardness Tests

- Load Range: from 10 grams to 2,000 grams, allowing for testing of a variety of materials and hardness scales.

- Measurement Accuracy: within ±1% of the applied load, ensuring reliable and repeatable hardness values.

- Multiple Hardness Scales: including Vickers, Knoop, and Brinell providing versatility for different material types and requirements.